Operational Qualification - OQ

DataApex Validator 2 and OQ Validation Wizard

The Operational Qualification (OQ) is a procedure designed to confirm that the data station is performing according to the manufacturer’s specifications. The Operational Qualification is provided by the Validation Kit (optional), which consists of a precise peak generator and a set of methods and reports used in the validation process. The System Suitability Test (SST) module, an optional Extension of Clarity, is necessary for running OQ.

How to use the Operational Qualification

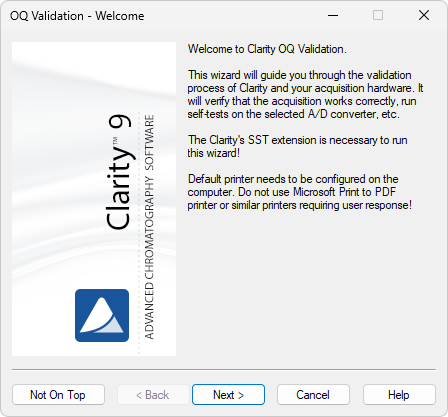

To perform OQ, run the OQ Validation Wizard from the Clarity\Bin\OQ_VALIDATION folder. The Wizard will guide you through the procedure of the OQ validation.

It is possible to perform OQ in two different ways:

1. Validation with an A/D converter

Colibrick or any other

2. Validation with a Virtual detector

For systems with digital acquisition, this is the only feasible manner of validation. The input signal is simulated via the Virtual detector control module, which is able to simulate signal input into Clarity in exactly the same way as a real chromatographic instrument would do. This will ensure that digital signals are processed correctly after being received from a detector. Virtual detector is a part of the Clarity software, meaning no extra hardware or control module is needed for this type of validation.

Note:

OQ validation takes approximately 50 minutes to complete and during this time, it is not possible to perform analysis using Clarity.

The Validation kit (p/n: CVK) as well as the SST Extension (p/n: A22) can be purchased separately. The validation process is described in more detail in the Validation Kit manual (M039).